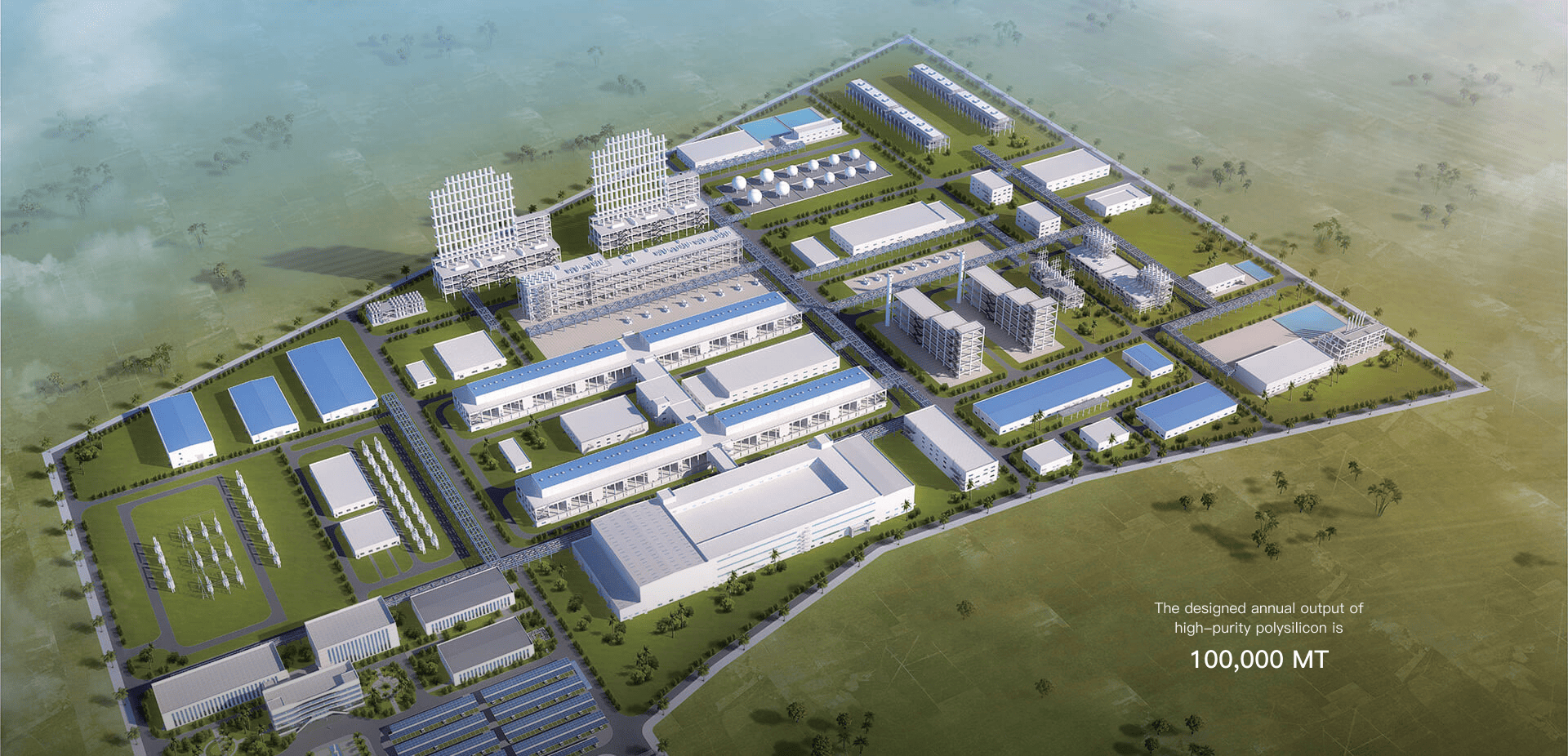

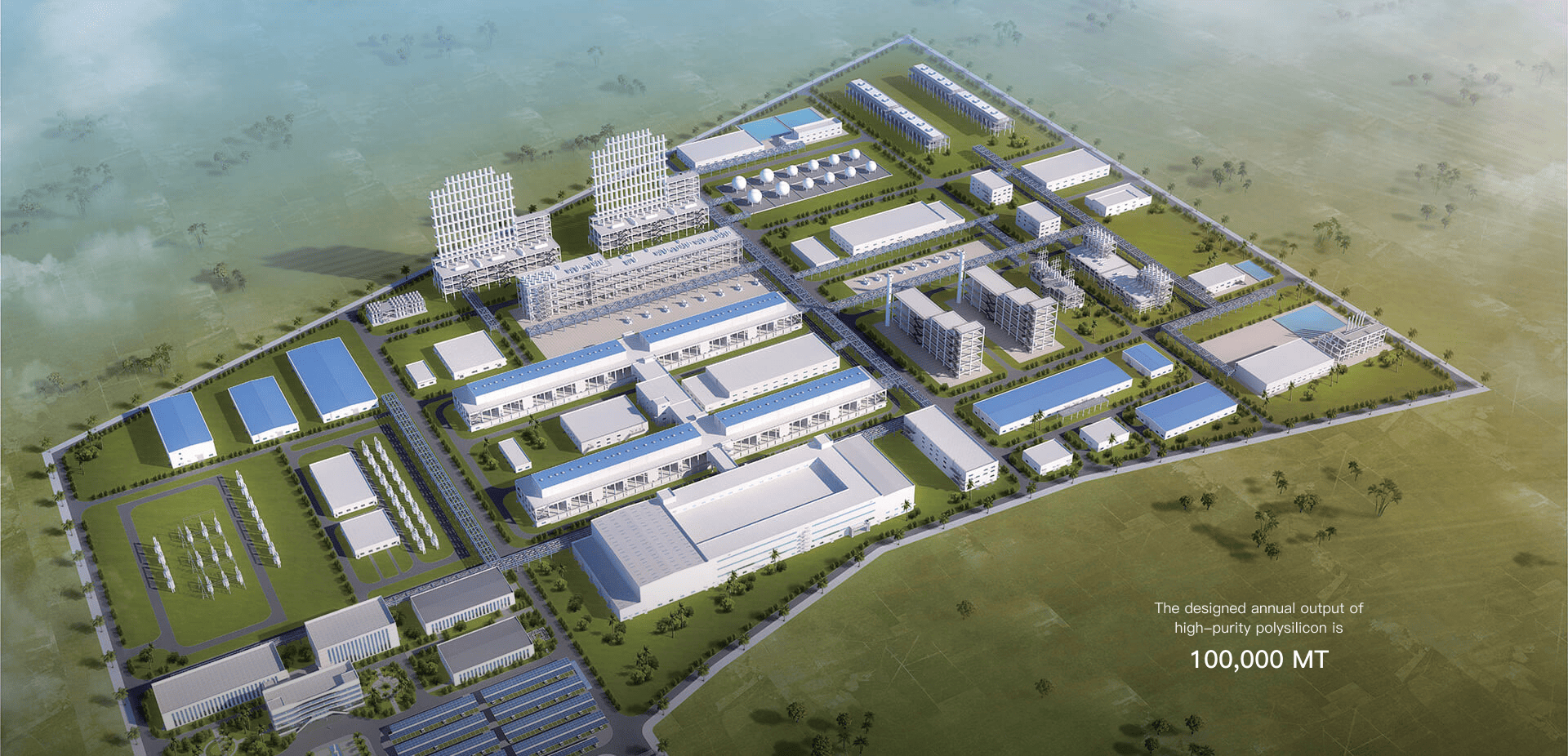

United Solar is headquartered in the Sohar Freezone of Oman. Oman was selected as our production base due to its strategic location, well-developed infrastructure, abundant natural resources, and access to global markets. Oman's longstanding commercial ties with the West and other rapidly growing markets make it an ideal base for serving international customers and promoting energy abundance.

The company is led by over 50 experienced solar energy experts, with a team that combines strong technical capabilities and international project experience. Focusing on the global polysilicon market, the company places particular emphasis on product certification and research and development for the U.S. market.

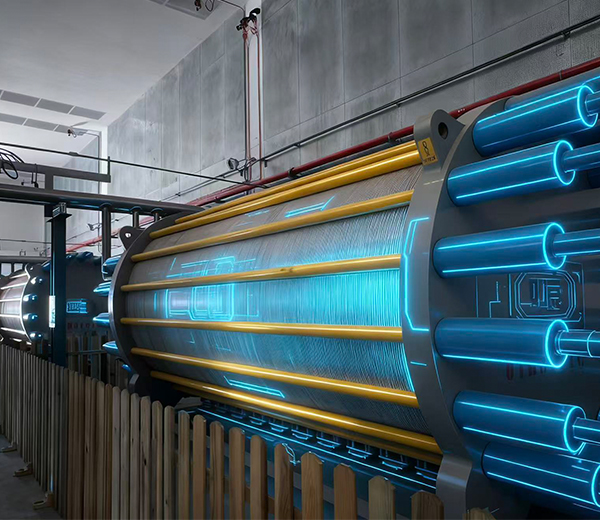

United Solar's state-of-the-art facility in Oman delivers best-in-class energy efficiency, the highest silicon conversion rates, and unmatched labor productivity—even in challenging hot climate conditions.

Enabled by advanced reactor design and control

Enabled by advanced reactor design and control

Boosts output per cycle

Boosts output per cycle

Reduce cost materially

Reduce cost materially

Hydrogen recovery reduces OPEX & footprint

Hydrogen recovery reduces OPEX & footprint

Only economically viable with large multi-core furnace

Only economically viable with large multi-core furnace

Higher throughput per reactor

Higher throughput per reactor

Longer continuous runs

Longer continuous runs

Superior on‑stream reliability

Superior on‑stream reliability

Maximizes first‑grade polysilicon yield

Maximizes first‑grade polysilicon yield

Reduces CAPEX & simplifies operations

Reduces CAPEX & simplifies operations

Enables ultimate heat recovery

Enables ultimate heat recovery

Zero wastewater discharge

Zero wastewater discharge

Strengthens compliance & sustainability

Strengthens compliance & sustainability

AGV led production & packaging

AGV led production & packaging

Minimal human involvement

Minimal human involvement

~200 people for 10 KTPA (Versus 5 KTPA historically)

~200 people for 10 KTPA (Versus 5 KTPA historically)

扫码关注